State-of-the-Art CNC Machining

Our state-of-the-art CNC Machining Centers allow us to produce highly precise and complex parts, with unparalleled accuracy. From our 4-Axis CNC Milling and Drilling/Tapping Centers to our CNC Lathe, we have the equipment to handle all your machining needs.

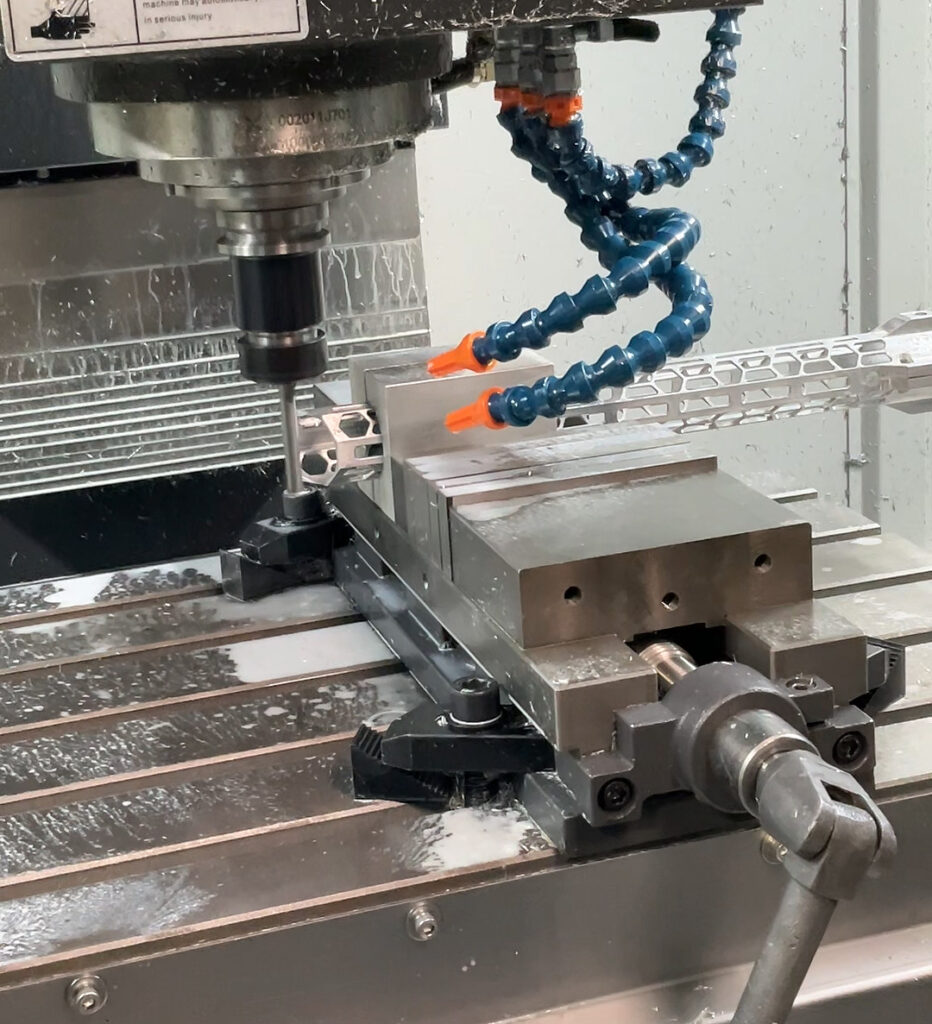

4-Axis CNC Vertical Machining Centers

We currently have 6 CNC Vertical Machining Centers. Our vertical machining centers are high-performance, four-axis CNC machines designed for a range of operations including milling, drilling, tapping, and boring, suitable for both rough and precision machining in manufacturing and mold making. They feature high-speed, high-rigidity spindle systems driven by servo motors, ball screws and linear guides, and robust cast iron structures optimized via finite element analysis for stability and durability. Equipped with a 24-disc automatic tool changer (ATC), full protective enclosure, CNC controller, lubrication system, and various accessories like a cooling system, air gun, and chip tank, our CNC Vertical Machining Centers ensure high surface quality and precision.

4-Axis CNC Drilling/Tapping Centers

We currently have 3 CNC Drilling/Tapping Centers. Our Drilling and tapping centers are specialized CNC machines designed for high-speed, high-precision drilling and tapping, often with milling capabilities as well. They are optimized for efficient and repeatable production of parts with multiple holes and threads, especially in high-volume manufacturing. Equipped with a 21-disc automatic tool changer (ATC), full protective enclosure, CNC controller, lubrication system, and various accessories like a cooling system, air gun, and chip tank, our CNC Drilling/Tapping Centers ensure high surface quality and precision.

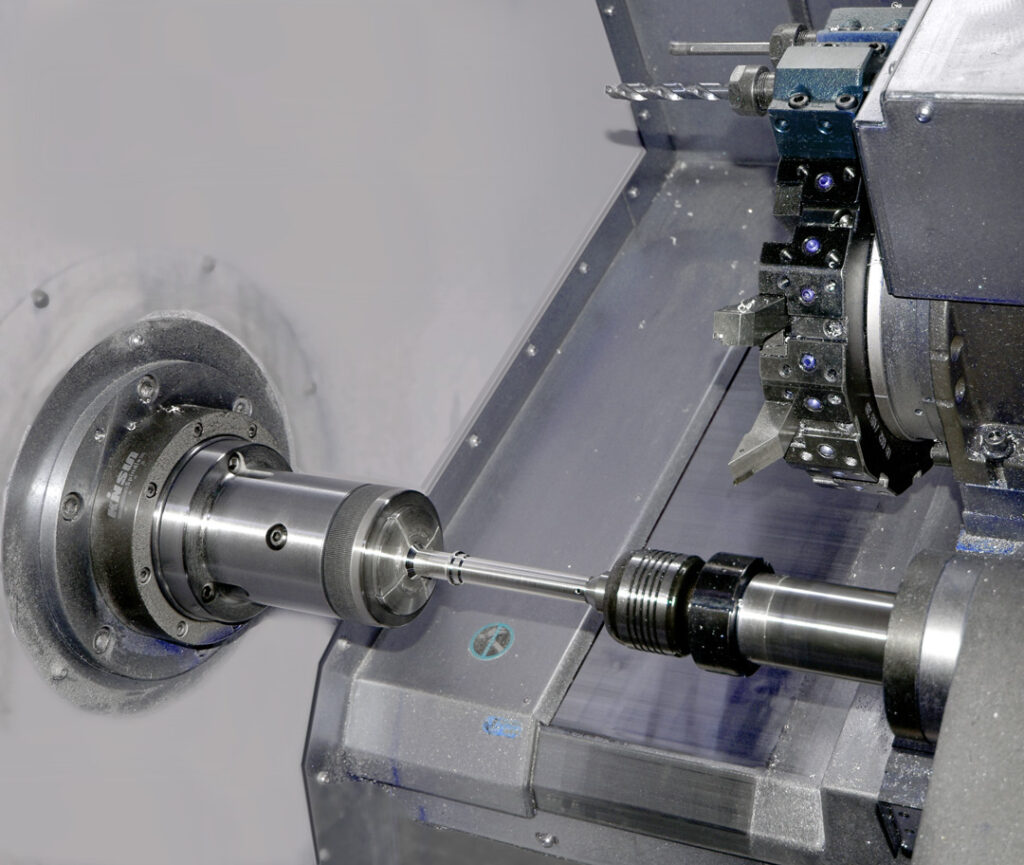

Slant Bed CNC Lathe

We currently have 1 Slant Bed CNC Lathe. Our CNC lathe delivers high accuracy, high speed, and high precision, utilizing a 12-station-power turret. It is a CNC turning center with a bed tipped at an angle. It is designed so that chips removed from the workpiece fall away more freely from the machine as it continues the cutting process. Its tipped design also enables larger X-axis travels, making more cutting lines, flexibility, and capacity possible. It is suitable for both rigid and precision turning of disc and shaft parts, making it ideal for applications in the military, automotive, medical, and home appliance industries.

Versatile Machining Solutions

Whether you require prototyping, small-batch production, or large-scale manufacturing, Presma Inc Manufacturing has the expertise and resources to deliver exceptional results. Our team works closely with clients to understand their unique needs and provide tailored machining solutions.